Monitoring and control of the refrigeration equipment temperature regime

-

Customer

Leading Russian food retail company. The company operates several retail chains: convenience stores, supermarkets, hypermarkets, Express Retail stores under different brands.

The Company operates more than 13,500 stores with leading positions in Moscow and St. Petersburg, more than 40 distribution centers and more than 3,500 own trucks in the Russian Federation.

-

About project

- Integration of refrigeration equipment: 300,000+ automation units (monitoring units and refrigeration equipment controllers) in 13,500 stores in Russia

- Monitoring of operational parameters with the possibility of automatic adjustment and automatic notification of the Customer’s staff about incorrect settings and operating modes of refrigeration equipment in the retail chain’s stores

- Preservation of energy efficiency of automation and refrigeration equipment use

- Reducing the cost of repair, restoration and scheduled maintenance of automation and refrigeration equipment

-

Goals

Automated continuous monitoring of the configured parameters and operating modes of automation and refrigeration equipment for a limited period of time:

- control of temperature and technological modes of automation and refrigeration equipment operation;

- identification of violations related to configuration of system controlled parameters and operation modes of automation and refrigeration equipment.

Generation of control events in the Customer’s monitoring system to change the settings of automation and refrigeration equipment parameters.

Possibility to define individual rules for identification of violations in the operation of automation and refrigeration equipment and options for response to arbitrary violations, including:

- alerting supervising users (user groups) about identified abnormal situations;

- integration with Customer’s corporate systems.

Provision of reports on operation of automation and refrigeration equipment and status of the controlled in the System to users.

Features and implementation indicators

Monitoring and control of operating parameters of more than 300,000 units of automation and refrigeration equipment:

- acquiring current status and operating indicators of refrigeration equipment;

- normalization of data received from equipment of different manufacturers of refrigeration equipment;

- generation of the list of operating parameters of automation and refrigeration equipment for control;

- generation of individual rules for control of main operating parameters of automation and refrigeration equipment, depending on the operation type and mode;

- automated identification of violations in settings and violations related to operation of connected equipment in specified operating mode of automation and refrigeration equipment;

- automated retrieval of information about current accidents from controllers.;

- sending alarm messages to the Customer’s corporate systems in case of identification of violations and notification of supervising users (user groups) of the System;

- generation of tasks to change automation settings of refrigeration equipment;

- maintenance of service registers and reference tables necessary for the operation of the System.

Interaction with internal corporate information systems:

- retrieval of information about Customer’s facilities from corporate systems;

- maintenance of reference tables and their alignment with Customer’s corporate systems.

Report generation:

- preparation of data showcases for the generation of reports in specialized systems of the Customer;

- management of the System configuration parameters;

- uploading data to Excel and integration with SAP corporate reporting systems.

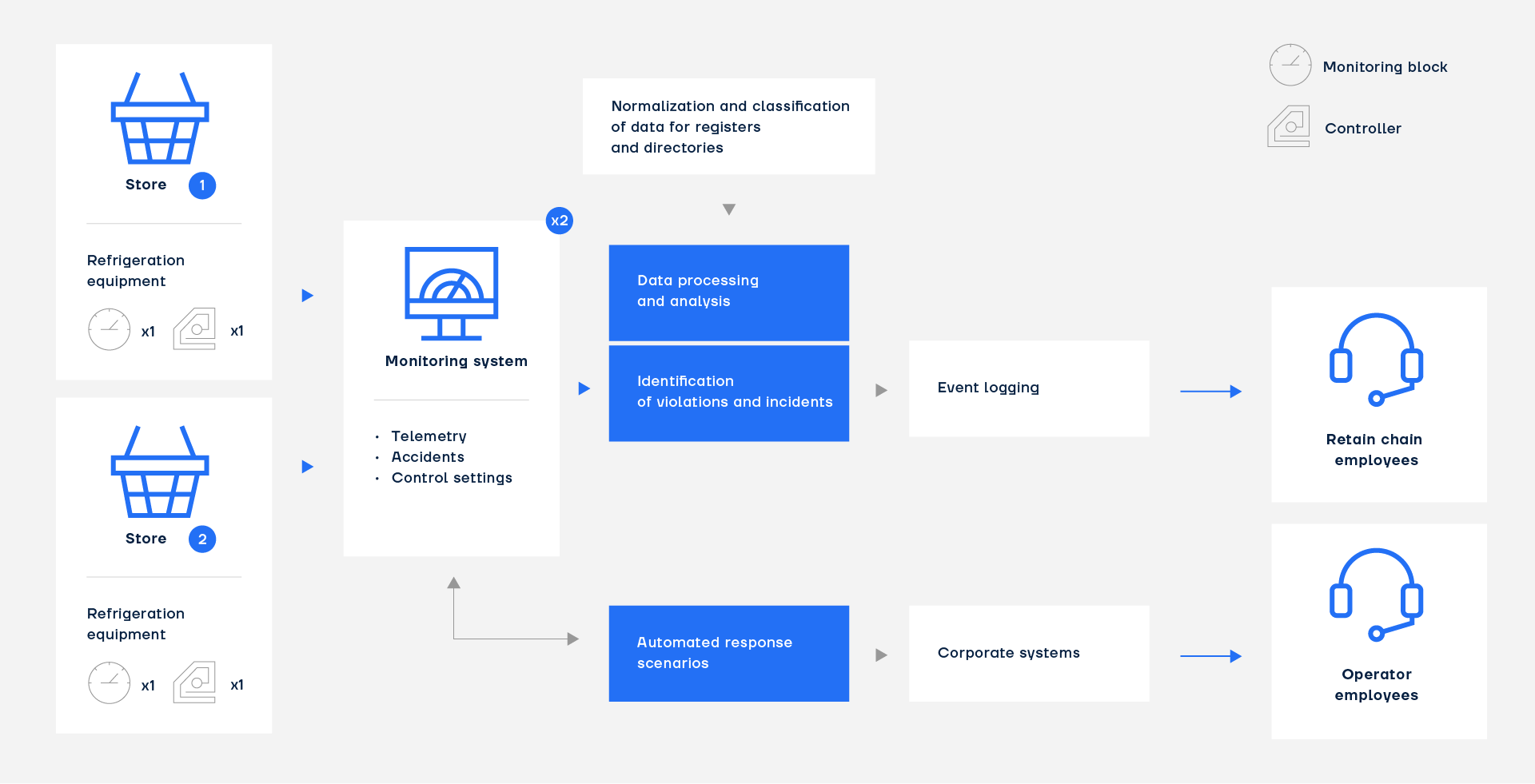

Architecture of refrigeration equipment operating temperature regime control system (general)

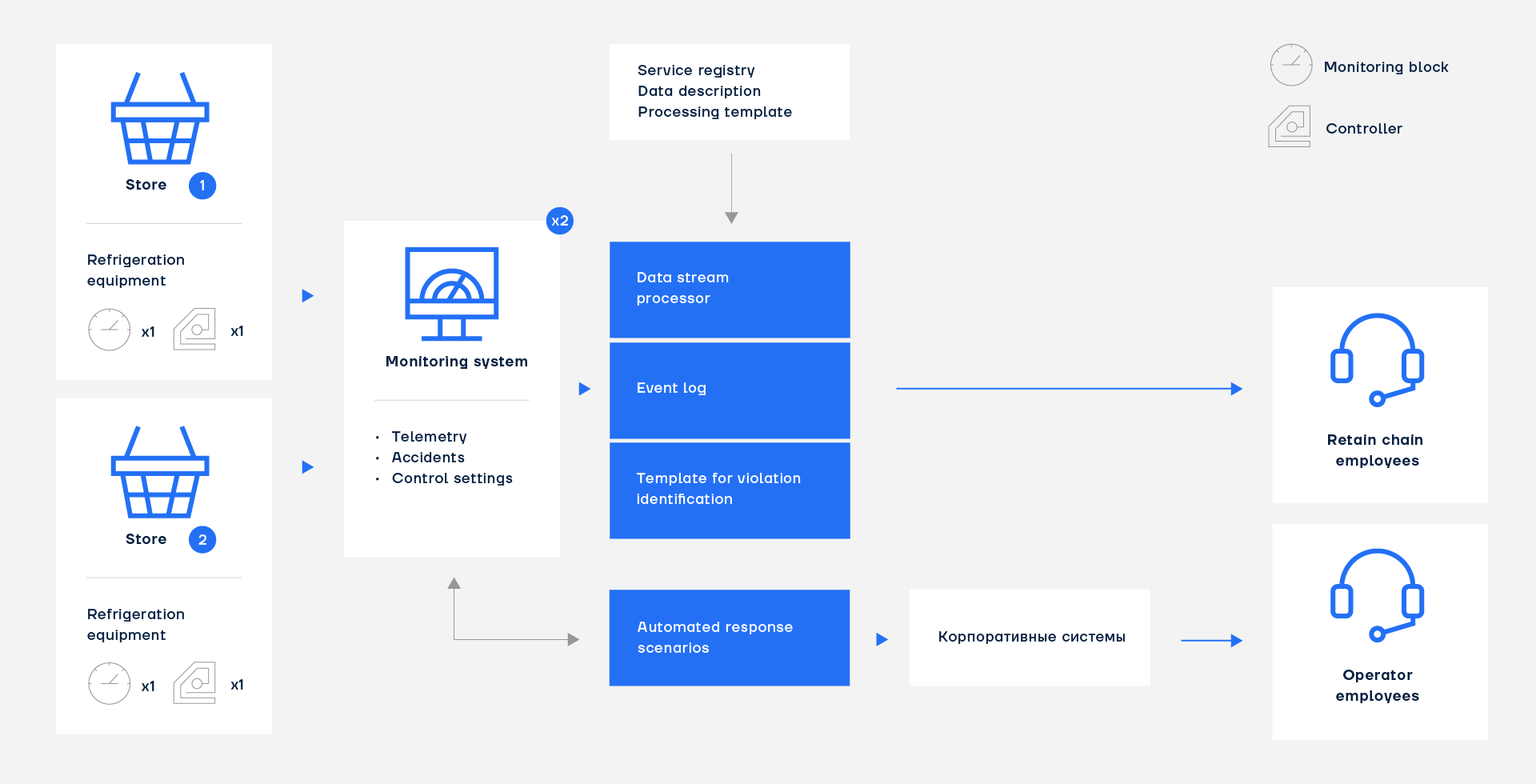

Architecture of Customer’s refrigeration equipment operating temperature regime control system

- Разработка первых на российском рынке методологии и стандартов контроля температурного режима холодильного оборудования по сценарию интернета вещей

- Создание базы для быстрого и эффективного внедрения проектов по сценарию интернета вещей в будущем

- Доработка существующих интегрируемых информационных систем с целью создания единой цифровой экосистемы

- Настройка логики обработки поступающих данных от холодильного оборудования

- Создание «умных сценариев» обнаружения важных и критичных инцидентов

- Адаптация ПО под IT-ландшафт заказчика

- Круглосуточный непрерывный мониторинг параметров температурных режимов всего парка холодильного оборудования Заказчика

- Автоматизированная настройка установленных параметров температурных режимов оборудования, в случае отклонения от заданных параметров

- Достоверный контроль коэффициента энергоэффективности оборудования позволил снизить затраты на электроэнергию, что приносит экономическую пользу компании в краткосрочной перспективе и демонстрирует заботу об экологии Планеты и ответственное, бережное ведение бизнеса

- Автоматическое обнаружение нарушений в настройках температурных режимов оборудования и контроль аварий

- Оповещение сервисных организаций и ответственного персонала в режиме реального времени в случае нештатных ситуаций с холодильным оборудованием (аварийные ситуации, потеря связи с устройством, нарушение температурного режима, отсутствие части показателей телеметрии и т. д.) и ответственного персонала в нештатной ситуации с обслуживающими сервисными организациями